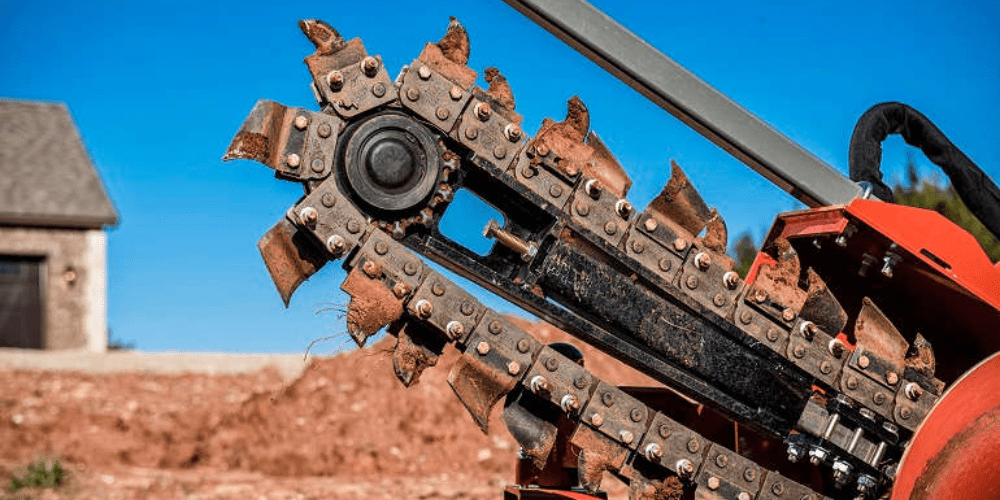

The specifications of trenching teeth can vary depending on the manufacturer and the specific type of tooth. Common specifications to consider when selecting trenching teeth include tooth size, tooth shape, tooth material, and tooth attachment method. The type of trenching teeth used will depend on the specific soil conditions and the type of trenching operation being performed. It is important to choose the right type of teeth to ensure the most efficient and effective trenching operation.

Types:

There are several types of trenching teeth available for use in trenchers. Some of the most common types include:

Cup teeth:

These are typically used for trenching in soft to medium-hard soil conditions. They are designed with a cup-shaped cutting edge that helps to scoop out soil as the trencher moves forward.

Performance:

These teeth are designed to work best in soft to medium-hard soil conditions. They have a cup-shaped cutting edge that helps to scoop out soil as the trencher moves forward. They can work well in sandy soil, but may struggle in harder soil conditions.

Shark teeth:

These are used for trenching in hard soil conditions. They are designed with a sharp, pointed cutting edge that can easily penetrate through compacted soil and rock formations.

Performance:

These teeth are designed to work best in hard soil conditions. They have a sharp, pointed cutting edge that can easily penetrate through compacted soil and rock formations. They are ideal for trenching in areas with lots of rocks or roots.

Rock teeth:

These are used for trenching in rocky soil conditions. They are made of tungsten carbide material and are designed with a conical or bullet shape that helps to penetrate through hard rock formations.

Performance:

These teeth are designed to work best in rocky soil conditions. They are made of tungsten carbide material and are designed with a conical or bullet shape that helps to penetrate through hard rock formations. They can work well in softer soil conditions as well.

Heavy-duty teeth:

These are designed for use in tough soil conditions, such as frozen ground or clay. They are typically made of stronger materials, such as steel or high-grade tungsten carbide.

Performance:

These teeth are designed to work in tough soil conditions, such as frozen ground or clay. They are typically made of stronger materials, such as steel or high-grade tungsten carbide. They can be effective in a variety of soil conditions but may struggle in sandy or loose soil.

Combination teeth:

These are designed with a mix of features, such as a cup-shaped cutting edge and a sharp, pointed tip. They are versatile and can be used in a variety of soil conditions.

Performance:

These teeth are designed to work in a variety of soil conditions. They have a mix of features, such as a cup-shaped cutting edge and a sharp, pointed tip. They are versatile and can be used in many different trenching applications.

The size and shape of the tooth should be matched to the size of the trencher and the specific trenching application. The tooth material should be chosen based on the soil conditions and the desired level of durability.